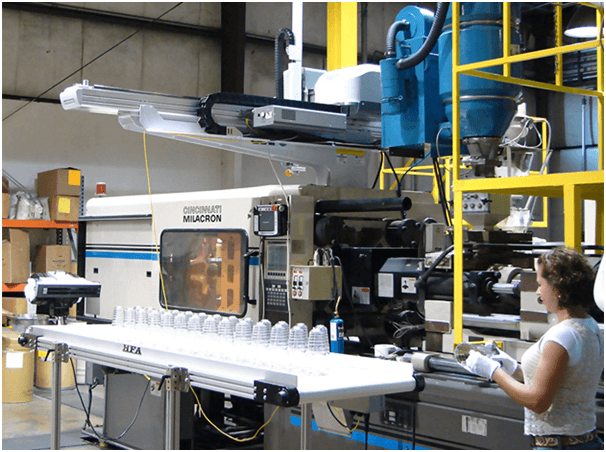

Plastic molding refers to a technique used in manufacturing a well as producing various parts. It’s also a method used by multiple plastic injection molding companies in creating products. It’s vital to note that this is a preferred method used in the production of different commodities. Some benefits come with the process of plastic molding manufacturing.

- Enhanced Strength In Production

Plastic

molding is an intense process used in the manufacture

of different commodities. For it to be successful, some devices need to be

applied. Strength is, therefore, one of the critical elements that should be

considered when manufacturing the plastic injection molding part. The

manufacturer needs to understand the requirements of the product. This will aid

in adjusting parts of the molding machine. With that said, knowing how the

client will use those parts is of importance.

- High Production Efficiency

During the manufacturing process, the injection mold will be

designed. Immediately this has occurred, the client’s specifications and

preferences are pre-programmed. Therefore, the actual manufacturing process

entails a quick injection technique subjected to different methods of molding. After

that, the plastic injection will take a few minutes before more parts are

harvested from one mold. The voluminous production rate is not only efficient

but flexible.

- Cost-effective

Most manufacturing companies prefer to use plastic injection molding

since the method is cost-effective. The high rate of production facilitated by

the use of a single molding material can be subjected to a hot-runner ejection

system. In the end, it’ll produce more parts that have a consistent

quality.

- Complex Part Design

Injection

molding is a viable process that can easily handle

complicated parts during the manufacturing process. These parts may have been

subjected to intense pressure. To optimize the effectiveness of the injection molding

technique on the components being manufactured, the primary design factor needs

to be considered. As such, a compact design should be developed. This helps in

maximizing its efficiency.

- Enhanced Flexibility

Selecting a preferred material as well as color

for the project is an essential consideration in manufacturing plastic parts. Because

of the variety of materials in the industry, the chances of selecting the right

equipment are endless. With that said, advances and development in polymers

have majorly contributed to the growth of a significant selection of various

resins. It’s vital to select the right material for your project. Plastic injection molding companies

have the means to make this possible for you.

- Providing Several Finishes

Plastic

molding is a process that can be used by those whose plastic parts need a

smooth finish. The technique subjects these plastic parts to significant

pressure that can shape any object. If you don’t prefer a seamless look on your

object, the plastic molding will ensure that you achieve a rugged finishing.

Take-Home

For you to enjoy the

benefits of plastic molding, manufacturers need to work with high-profile

injection molders that can provide excellent services. The listed advantages of

plastic molding should also push you towards working with a professional

service provider.