Plastic

injection molding is one of the most popular methods for manufacturing parts in

the world. It is a versatile, simple, reliable, and very efficient method that

holds numerous advantages over other plastic molding methods.

There shouldn’t be any doubt as to why plastic injection molding is and should be anyone’s top choice for parts manufacturing. To clear the waters for those that lack the facts on this matter, here are the top 5 reasons why it is the preferred production method for thousands of manufacturers worldwide.

1. Top Efficiency

Once the

injection molds are built according to the customer’s plans and technical

specifications, and the presses are programmed, the remaining process is very

fast compared to other types of molding.

It is a

process that has a high output production rate, can produce multiple parts from

a single mold, fast cycle times, all while producing consistent quality. All

that translates to a cost-efficient and effective manufacturing production

method.

2. Excellent Strength

Sometimes

fillers are added in the injection molds to reinforce the strength of the

parts. That’s when parts need to be durable, strong, or are in a harsh

environment that puts them at a lot of pressure. Plastic injection molding is

one of the rare processes that allows adding fillers to increase the strength

of the manufactured parts.

3. Combine Various Plastic Types Simultaneously

Co-injection

molding is a feature that allows for combining different types of plastic at

the same time. It is one of the prevailing reasons why many manufacturers love

plastic injection molding.

4. Automation

Plastic

injection molding is a process that mainly relies on robotics and machines. In

most cases, a sole operator is all the human help needed to manage and control

the entire process. The reduced labor force lowers the production cost. Lower

cost of manufacturing is the direct path to increased profit margins, which all

businesses love to see.

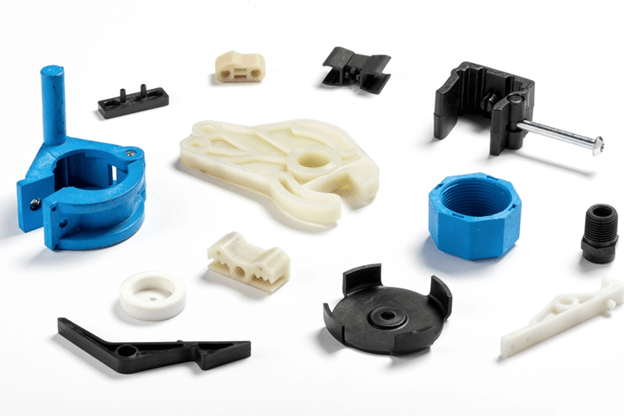

5. Complex Geometry and Detailed Features

Injection

molds are treated under very high pressure. Thanks to that, when plastic is

inside the mold, it is pressed very hard against its walls. That pressure is

much higher than in any other molding process. That makes it possible to

produce parts with detailed features and complex geometry.

All other

molding processes are either too expensive or too complicated, while that’s not

the case with plastic injection molding. The level of complexity and the

intricate shapes possible with this molding process are by any account vastly

impressive.

To Conclude

Plastic

injection molding is the type of process from which you get finished products

that don’t require additional rework. That’s just one of the many reasons why

manufacturers are in love with this process.

Last but

not least, plastic injection molding is an eco-friendly process. All the

plastic scrap that is produced during the production can be easily re-grounded

and re-used. That means little or no waste at all.