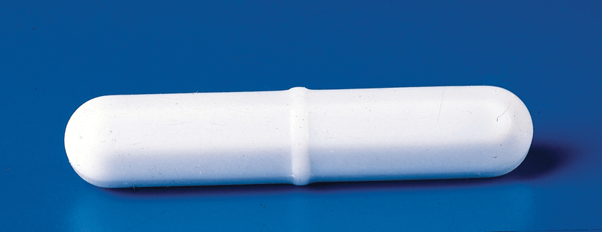

PTFE materials are made of synthetic fibers known as polymers. The polymerization of these elements leads to the production of different elements, including bars. PTFE bars have unique properties. One of these traits is a high melting point. It is also stable at a variety of temperatures. This implies that the bars can easily be dissolved by fluorine gas only. Other materials will not affect them in any way. In this article, by Teflex Gasket Company Limited, we shall discuss the general observation of PTFE bars, including why most manufacturers prefer to use the material in producing different compounds.

Let us look at the top reasons why PTFE

bars are used in these sectors.

PTFE

bars are slick. They are also slippery, making them an

ideal material for the coating of machine parts. Usually, in many cases, you

will find out that the machine parts are often subjected to friction and tear

and wear. They may also be exposed to corrosive chemicals.

Additionally, the bars may be broken down

and processed to impart some element of stain-resistance not just to fabrics

but wall coverings as well. Because these materials are not highly conducive to

electricity, it is used as a primary electrical insulator in communication

cables. It is also a relevant material used in the manufacture of various

semiconductors.

PTFE bars generally contain essential

elements that can be used in the design of different medical applications,

including vascular grafts. In the event that there is the need to process roofs

at stadiums, these materials will also be used. PTFE is known for its use in

making socks. The bars are, therefore, commonly used in protecting the user’s

feet from blisters.

That said, it is clear that the

polymerization process enables molecules to combine into a chain of strings.

Nylon is just one of these polymers.

Discovered in 1929, the material was known not to be able to polymerize. But

over the years, most professionals embraced it. That is why the use of this

material has been on the rise of late.

The polymerized chemical of PTFE materials was inert.

This means that it failed to react with other elements, thereby resisting

electric currents. After realizing that the gas polymerized, Plunkett, the man

behind the discovery of PTFE bars, realized that it was crucial to take a

patent for this compound. Since then, the material has become useful to many

industry professionals.

Conclusion

In the past, PTFE bars were costly. The

value of these products was not really clear to the initial dealers, including

scientists. The applications came into use around World War II. And at that

moment, the atomic bomb was being created. Scientists handled large amounts of

different toxic substances. PTFE bars and other related materials were also

used to make nose cones.

Just a notable point, it is important for

quality control measures to take place during the creation of PTFE materials

such as the bars. The processing procedures must be followed to the end. This

will play a role in determining the quality of ingredients used in the long

run.