The efficiency and quality of 3D metal printing have significantly improved. These are used, and they serve as machining services in years past.

Though the printing methods have been present since the year 1981, they have gotten quite sophisticated, and they have more clarity levels.

This article would break down and explain all of the uses of 3D metal printing. Read along and enjoy.

Understanding how Metal Printing works- 3D Printers

The 3D printer already has its settings from the producer. Because these settings are already sent, all the user needs to do is send the settings file to the machine, and with luck, great results await you.

These 3D printers are created to forge plastic. A lot of producers have enjoyed lots of advantages using these printers.

Explanation of how 3D printers Work

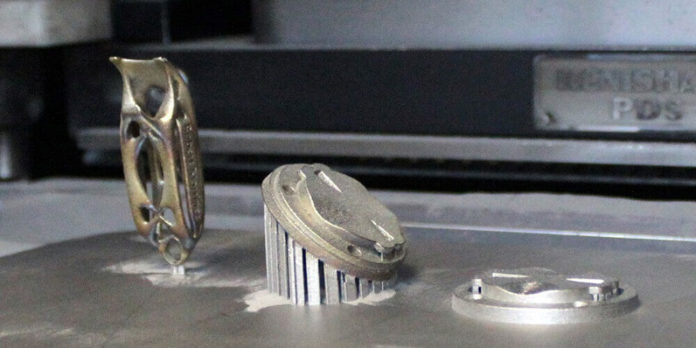

There are several methods and approaches to carry out printing using metals. There are just two, though, that are correctly recognized. These methods are highly used because of how effective they handle a task. These methods include selective laser melting and binder jetting.

1. Binder jetting

This is known as the method which handled materials efficiently. Amongst the two types of 3d printers, binder jetting is used often by many people.

How is the Binder Jetting method used?

While using the binder jetting, You get to build a chamber using argon to prevent oxidation of your metal. Then, ensure that you spread out metal powder at around 20/50 microns in thickness. The 3D printer would then spray a compound made out of polymer using three regions of the metal. These would all depend on the 3D outline. You can repeat this entire process until you’re satisfied with the outcome.

2. Selective laser melting

Asides from the binder jetting, selective laser melting is the next most used technique. It’s equally efficient when you want to make high-quality 3D metallic prints.

How Selective Laser Melting is used

- First, you build your chamber, making use of inert gas.

- You should use the machine to spread a fragile metal powder all across the surface.

- The laser would fuse with the powder and then use a solid layer of the object you want to create.

- Then, you use a whiter metal powder layer that you spread all across the floor from fifty to two hundred.

- The laser would continue fusing with this metal powder layer, and it wouldn’t stop till your object is created using the 3D design.

Final Thoughts

Looking at both of these methods, you need to gather all the emailing powders. You can use this powder for other machining services in the future instead of leaving the powder to waste like that. This would end up reducing the rate at which you would have wastes from the leftover metal. Also, this is a way of reducing the cost of purchasing more metallic material. With this article, you should have a lot of knowledge on handling or using 3D metal printing machines.