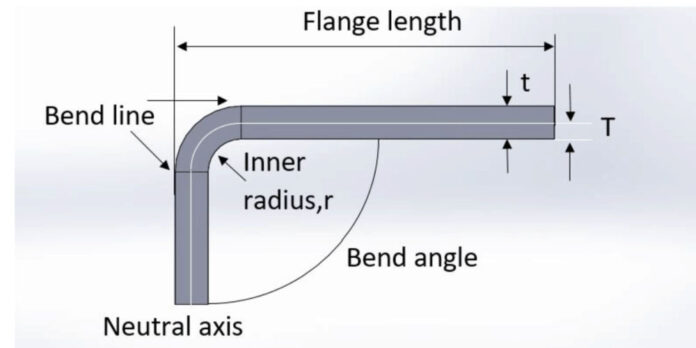

The sheet metal bending process leads to the development of both complex and simple parts used for various economic reasons. Its necessity in creating durable parts has made it quite popular in the aerospace industry. For example, sheet metal bending is used to create an aircraft’s wings. Furthermore, its popularity has drawn the attention of many. Therefore, this post will provide you with frequently asked questions about the sheet metal bending process.

Frequently asked questions about sheet metal bending process

1. Are there different kinds of sheet metal bending?

Different kinds of sheet metal bending exist. The purpose of the various bending is because different shapes require different bending techniques. Thus, different bending machines are used. The different kinds of sheet metal bending include; bottoming, air bending, folding, coining, roll bending, wiping, and step bending. Therefore, the type of sheet metal bending you use will depend on the kind of shape you want and the machine used.

2. What are the different types of equipment used in the sheet metal bending process?

There is different sheet metal equipment used in the bending process. The various equipment used ensures high accuracy levels, efficiency, and quality. The different equipment includes; pneumatic bending equipment, hydraulic folder machines, rotary sheet bending machine, sheet bending presses, electromechanical bending machine, and automatic sheet metal bending machine.

3. What is the best aluminum grade for the sheet metal bending process?

For the effectiveness of the sheet metal bending process, it is ideal to use the right aluminum grade. Different aluminum grades have different malleability. Thus, it is essential to have a suitable grade before you begin the sheet metal bending process. The best aluminum grades include; 5005, 1050a, and 5251. The 1050a is best used when only moderate strength is needed; it is also very bendable. The 5251 is best used where high corrosion resistance is required. Therefore, it is best used in the marine industry application.

4. Does the sheet metal bend process change a material’s characteristics?

Sheet metal bending involves material deformation. But, the critical point to note is that the bending process will not change a material’s property.

5. How long does sheet metal processing take?

A Sheet metal processing time depends on the type of part you want and the material used. Simple parts take a shorter time in comparison to intricate parts. Furthermore, the designing of information has to take precedence. Thus, part drawing needs first to take place before the manufacturing process commences.

6. Is it possible to avoid breaking stainless steel while bending?

It is very much possible to avoid breaking stainless steel while bending. You will need to heat the bend from the inside instead of the outside. Stainless steel material is relatively weak when heated. Thus, the material can tear while hot. Consequently, heating from the inside will reduce the chances of the material breaking.

Conclusion

Sheet metal bending involves different processes. The various techniques require different materials and shapes to be effective. Furthermore, different equipment is used for the sheet metal bending process. Thus, it is essential to know all facets related to sheet metal bending.