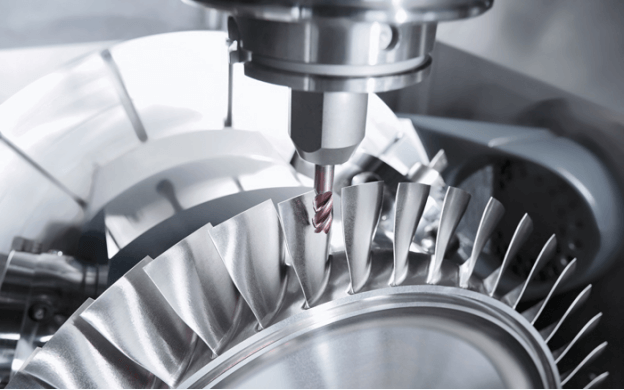

There are some reasons a company will employ the 5-axis machining in its manufacturing process. The most prominent reason is that it enables them to carry out a more complex component machining.

But having such kind of machining is as important as understanding it, and how it fares against the alternatives. This piece will be highlighting the components of the 5-axis machining, and why you should consider it over other similar alternatives.

What is 5-axis machining?

5-axis machining (also known as CNC machining) is the process of using CNC (Computer Numerical Control) to make moving part(s) of a cutting tool on 5 separate axes at the same time.

This means that the cutting tools will be able to elaborate and intricate parts with the help of the 5-axis machining.

With that stated, the 5-axis machining came at such a time when there is a forward trend towards lead time reduction and a single setup configuration. This makes CNC machining a perfect fit for complex applications (notably aerospace).

It is also something an organization with manufacturing and machining processes should consider if they want to maintain geometry access and position of their cutting tool.

What are the 5 axes?

To explain the 5 axes present in a 5-axis machining system simply, we consider the X, Y, Z Cartesian axes. Their rotational axes A, B, C. This means that X has the rotational axis of A, Y has B, and Z has C.

Naturally, we have six axes that way, but the last rotational axis (for Z) is not compulsory to have, as there’s not much functionality it adds. Thus, it is common to just omit the last axis and leave it at 5 (although there are full 6-axis machines).

How does 5-axis compare?

When compared with the 3+2-axis machining, 5-axis machining has the advantage of having less wear and tear over time, as the movement along the axes is indexed. It is easier to program than a 3+2-axis machining.

In case of 3D printing and 5-axis machining, there is not much to talk about how the former is better than the latter or vice versa. Industry experts have identified that they both could be used complimentarily rather than in a substitutive manner.

Conclusion

5-axis machining has its advantages and disadvantages, but there’s no denying the fact that the consensus on the cutting process is leaning towards the machining system.

If your company decides to choose the 5-axis machining process, you should have come to terms with the mode of operations and how it directly affects the cutting process in the long run.

Also, it is pertinent to try to picture how to utilize it for specific cutting processes fully, or if some other alternatives are just more fitting to your needs. Although there are very rare occasions that 5-axis machining cannot be used in a component manufacturing process.