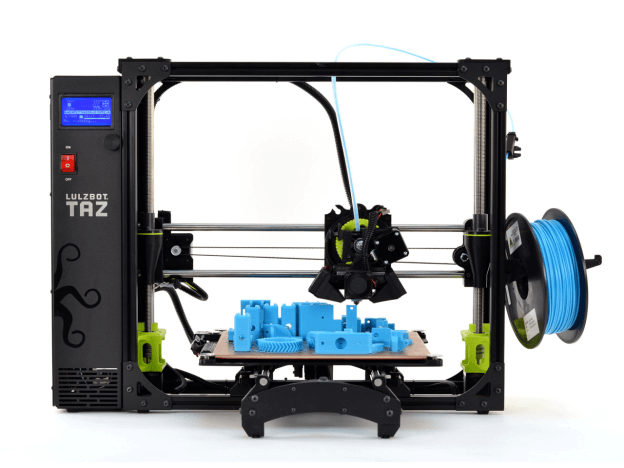

There are countless sorts of 3D printers in the market. These types fall under nine main categories of 3D printers. These categories are SLA, selective laser sintering, DLP, laminated object manufacturing, FDM, electronic beam melting, binder jetting, and material jetting. FDM, known in full as fused deposition modeling, is the most common category. It is a printing process used to produce objects one layer after another. The method was developed in the early 1980s, and it is used in the production of functional prototypes, manufacturing aids, and concept models. Like the other modes, it is an accurate means of 3D printing. In this post, we discuss the components of an FDM 3D printer like the PTFE Teflon tube.

- The build area

This component is the part of the 3D printer where the object is placed. The size of the build area depends on the maximum size of the item intended to be printed on the machine. The size is, therefore, measured in XYZ dimensions.

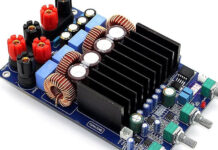

- The HOT End

Perhaps this is the most crucial component of a 3D printer. This is, therefore, the part of the printer where the plastic is melted and later extruded in small layers. When determining the best type of hot end from the mass in the market, it is essential to look into the maximum temperature it can handle.

- The Teflon tube

The Teflon tubes are the component that gets extended from extruders all the way to the hot end of the 3D printers. The Teflon tube allows for the 3D printing filament to be able to travel through towards the hot end. The tube comes in a variety of sizes and is made from different materials like PTFE. The standard size for a Teflon tube 1.75mm. However, it can be larger, depending on the brand.

- The Filament

Filament refers to the material that is used in 3D printing.

- The Nozzle

The nozzle is located at the tip of the hot end. It is the part through which the plastic comes out. The nozzle can be switched from time to another. The size of this component varies between 0.25mm and 0.75mm. However, the most common size if 0.55mm, and it can be changed to larger or smaller depending on the task at hand.

- The Extruder

The extruder is the component of the FDM 3D printer that feeds the filament to the hot end. There are two primary types of extruders. The first one is a direct extruder. This type the one where the filament is fed to the hot end directly from the spindle. The other type is bowned extruder. The bowned is where the filament is supplied to the hot end from a specific distance.

Final Take

Other parts of an FDM 3D printer include the heated bed that keeps the filament warm while printing. The cooling fan helps to cool down the final product. The print bed surface is the part on which the object is printed. All these parts work together to make the printing process a success.